A Comprehensive Guide to Identifying, Fighting, and Dealing With Undercut Welding Troubles in Your Welding Jobs

In the world of welding, encountering undercut concerns is an usual challenge that can endanger the structural integrity and overall quality of your welding jobs. Recognizing the root creates behind undercut welding, being able to precisely detect it in your welds, and carrying out efficient preventative actions are crucial skills for any type of welder. Furthermore, having the understanding and methods to remedy undercut problems when they do take place can make a significant difference in the final outcome of your welding endeavors. Remain tuned as we discover the vital components of recognizing, stopping, and fixing undercut welding troubles, giving you with valuable understandings and strategies to boost your welding abilities to the following level.

Typical Reasons of Undercut Welding

Undercut welding, a typical problem in welding processes, can be caused by different aspects that need to be very carefully recognized and dealt with to make certain the honesty of the weld joint. One of the primary reasons of undercut welding is excessive warm input.

One more usual reason of undercut welding is inappropriate welding strategy. Determining these origin triggers and carrying out rehabilitative measures is crucial in stopping and rectifying undercut welding problems in welding tasks.

Identifying Undercut in Welds

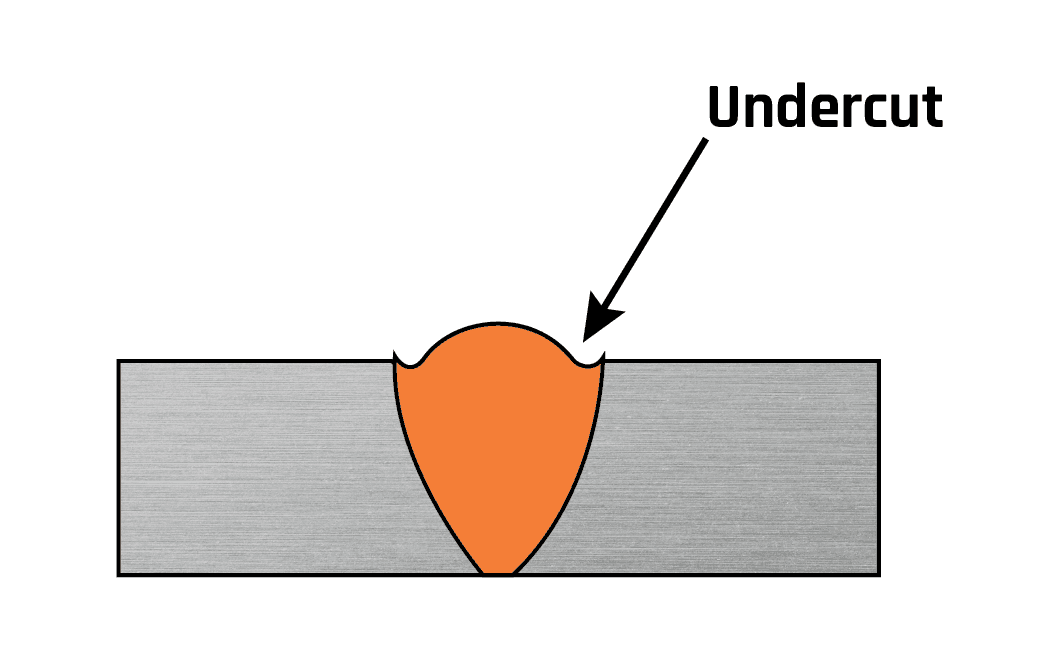

To determine undercut properly, appropriate lights and magnification devices are vital to check the weld joint thoroughly. Using tools such as a welding gauge or a magnifying glass can aid in finding even the smallest undercut imperfections. In addition, running a finger or a fingernail along the weld joint can sometimes expose undercut, as the surface area might really feel irregular or have a dip where the undercut exists.

Precautionary Measures for Undercut

Having a deep understanding of the sources of undercut in welds permits the application of reliable safety nets to keep weld quality and stability. One important safety net appertains weld joint prep work. Making sure that the edges are tidy, devoid of contaminants, and properly beveled can considerably lower the probability of undercut (Preventing weld undercut). Furthermore, choosing the proper welding specifications, such as voltage, present, and take a trip speed, is crucial. These setups ought to be maximized to avoid too much heat input, which can bring about undercut development.

Techniques for Repairing Undercut

Enhancing the welding existing or reducing the traveling rate can help load pop over to these guys in the undercut. In addition, transforming the welding technique from a press to a drag or vice versa can likewise assist lessen undercut.

An additional technique is to make use of a weaving movement while welding to ensure correct sidewall combination and fill in the undercut. By oscillating the welding arc from side to side within the weld joint, the welder can transfer much more filler product into the undercut areas, efficiently eliminating the issue.

In addition, grinding out the undercut and rewelding the joint can be a sensible service for much more severe undercut concerns - Preventing weld undercut. This procedure includes getting rid of the undercut section, preparing the base metal, and afterwards rewelding the joint with appropriate welding parameters and methods to prevent undercut from persisting

Specialist Tips for Staying Clear Of Undercut

Using proper welding methods and preserving control over vital welding parameters are essential Visit Website techniques for welders aiming to stop undercut in their weld joints. One expert suggestion for avoiding undercut is to guarantee proper joint preparation. This entails cleansing the base steel completely to get rid of any impurities that might bring about undercut formation. Additionally, selecting the proper welding process and filler steel for the specific application can aid stop undercut. Welders must additionally pay close attention to the welding current and voltage settings, guaranteeing they are within the suggested variety to avoid getting too hot and prospective undercut. Keeping a regular traveling rate during the welding process is an additional essential pointer to protect against undercut. By relocating at a stable rate, welders can make sure proper blend and lower the possibility of undercut formation. Checking the weld grain after conclusion can help determine any kind of indicators of undercut very early on, allowing for instant restorative action to be taken.

Verdict

To conclude, determining, stopping, and fixing undercut welding troubles in your welding projects is crucial for ensuring solid and long lasting welds. Preventing weld undercut. By comprehending the usual sources of undercut, having the ability to identify it in welds, executing precautionary measures, and utilizing proper methods for fixing undercut, you can stay clear of potential concerns and develop high-quality welds. Following expert pointers for avoiding undercut can help you improve your welding skills and create far better cause your tasks

Undercut welding, a common concern in welding processes, can be triggered by various variables that require to be meticulously recognized and addressed to guarantee the stability of the weld joint. Furthermore, running a finger or a finger nail along the weld joint can occasionally expose undercut, as the surface area may feel irregular or have a dip where the undercut exists.

Using appropriate welding methods and preserving control over vital welding specifications are crucial approaches for welders aiming to avoid undercut in their weld joints.In final thought, identifying, stopping, and dealing with undercut welding troubles in your welding projects is essential for guaranteeing long lasting and solid welds. By understanding the usual reasons of undercut, being able to recognize it in welds, carrying click to investigate out preventative steps, and utilizing correct strategies for repairing undercut, you can prevent possible problems and create top notch welds.